As Environmental Health and Safety Professionals, creating healthy environments is at the forefront of our minds as we navigate this new terrain as a direct result of COVID-19. As a mechanical contractor that serves clients throughout the United States, our clients looked to us to provide them with the best HVAC and plumbing solutions for their facilities, including solutions for building readiness to assist in creating healthy spaces for occupants, tenants, and their workforce. We did this by creating a facility plan for mitigating virus risk and increasing building safety. This is a three-phase approach starting with an audit to determine the building’s current readiness state, a look at potential upgrades that will help mitigate the risk of viral infections, and lastly, evaluate the efficiency of the filtration system to assure the system is operating at peek filtration optimization.

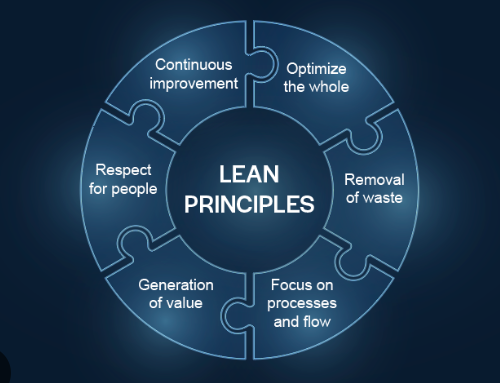

In the hierarchy of controls elimination, isolation, and engineering controls are the three most effective approaches to mitigating hazards. Our Audit/Update/Optimize approach follows these principles in creating a safer, healthier building for all.

HEALTHY BUILDING SOLUTIONS

AUDIT

How ready is your building for the latest healthy building solutions? What are you doing right, and what can you build on? What strategies can you implement to improve indoor air quality?

BUILDING READINESS

Evaluate to assure your facility is running at optimal levels. Evaluate current HVAC and plumbing systems to identify needed repairs, adjustments, or upgrades to enhance efficiency and operation.

SYSTEM DESIGN

Audit and adjust the amount of fresh air being introduced into your facility to achieve the ASHRAE and CDC recommended guideline.

ENGINEERED SOLUTIONS

Our professionally licensed engineers are here to help. Based on our findings from the building readiness and existing system design audits, we are able to provide engineered solutions and permit plans for any upgrade(s) that improve your facility.

UPGRADE

BI-POLAR IONIZATION

Bi-polar ionization is an emerging technology that can be installed in an HVAC unit’s air stream. Airborne particles are charged by these ions causing them to cluster, which improves filter effectiveness and overall air quality.

- Install a commercial quality, bi-polar ionization system into your existing HVAC system.

- The bi-polar ionization system introduces odorless, non-harmful ions into the air stream using the airflow of your existing ventilation system.

- Airborne particles are charged by these ions causing them to cluster, which improves filter effectiveness and overall air quality.

- These larger, harmless particles are now filterable and can be captured in air filter, providing cleaner air.

UV-C LIGHTING

Ultraviolet light has a long-standing reputation of creating healthy spaces. These lights can be installed in an HVAC unit’s air stream to mitigate viruses and bacteria while improving overall coil/ condensate pan cleanliness and efficiency.

Although the technology is relatively simple, ultraviolet light remains one of the most cost-effective solutions for maintaining a healthy indoor environment. These UV-C lights on your HVAC unit’s air stream deactivate viruses and bacteria while improving overall system efficiency

TOUCHLESS FIXTURES

Murphy specializes in designing and installing building automation systems that reduce the risk of viral transmission via surfaces with touchless technology. This decreases the opportunities for surface transmission by installing touchless fixtures and bottle fillers throughout your facility. Not only do these changes provide healthy environments, but they also serve as visual indicators of owner and property management safety initiatives.

OPTIMIZE

EXISTING AIR FILTRATION

Determine the highest filter efficiency that the equipment in your building can support. Evaluate the capacity and determine what will work best with your equipment without bogging down the efficiency.

Develop a filter change strategy that will help optimize the filter effectiveness of your investment.

FLUSHING AND TESTING

In today’s climate, you should be more prepared than ever to have the proper precautions in place for your facility. You probably have heard a lot about updating and improving your air quality, but did you know your water quality could be impacted as well? Have your plumbing system and water lines been flushed to assure a clean water system?

Legionnaires’ Disease is a serious type of pneumonia caused by bacteria, called Legionella, that live in water. Legionella can make people sick when they inhale contaminated water from building water systems that are not adequately maintained. Unfortunately, Legionnaires’ Disease is on the rise in the United States.

Your building may need a water management program to reduce the risk for Legionnaires’ Disease associated with your building water system and devices. This water management program should identify areas or devices in your building where Legionella might grow or spread to people so you can create a plan to reduce that risk.

CONTROLS INTEGRATION

Look for opportunities to utilize your existing Building Maintenance System, to develop a controls plan to improve the health of your building, creating a cleaner environment. Identify controls upgrades to optimize and improve your system.

There are many additional steps you can take to make your buildings safer, but these are just some of the many mechanical solutions that many overlook.

Author:

Rick Reams, SMS

Vice President Safety and Quality | Murphy Company

Direct: 314-692-1620 | Cell: 618-670-6589

Main: 314-997-6600

Email: rreams@murphynet.com | www.murphynet.com

Follow us: Facebook | Twitter | LinkedIn

If you want more information on our Healthy Building Initiative, please call: 314.997.5018 or EMAIL: SERVICESTL@MURPHYNET.COM